ISA-95 standards are seeing adoption across American manufacturing, with enterprise investments in industrial software and operational technology (OT) hardware projected to surpass $350 billion by 2030 (IoT Analytics). Recent implementations have already shown strong returns, with reported ROI ranging from 50% to 300%.

The updated ANSI/ISA-95.00.01-2025 standard, released in April 2025, directly addresses digital transformation needs with enhanced support for containerized workloads, cloud-hybrid architectures, and data-centric systems. According to analysis of more than 4,000 industrial automation projects by IoT Analytics, manufacturers implementing ISA-95-compliant systems have achieved significant operational improvements.

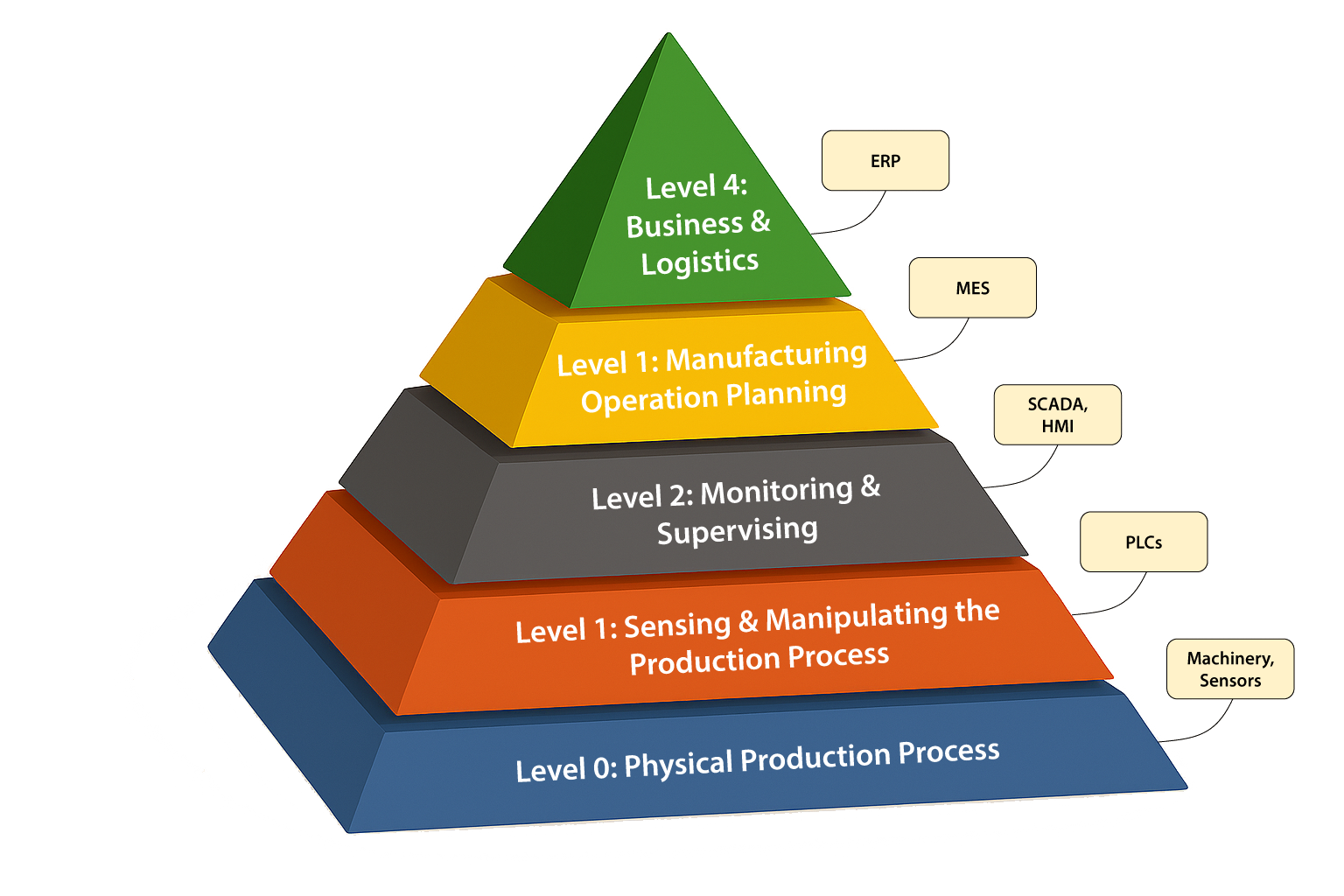

The framework’s hierarchical structure provides a critical foundation for bridging operational technology (OT) and information technology (IT) domains. This integration enables manufacturers to adopt Industry 4.0 and Smart Manufacturing capabilities—including AI-powered analytics, digital twins, and industrial IoT (IIoT) platforms—while preserving the operational integrity and regulatory compliance essential for American manufacturing competitiveness.

Delivering Measurable Transformation

American manufacturers are realizing significant operational gains through ISA-95 implementations, with adoption patterns visible across multiple levels of the manufacturing hierarchy. Rockwell Automation reports that 38% of its projects incorporate ISA-95 Level 3 solutions—primarily MES platforms like Plex—while Siemens shows even stronger adoption, with 58% of projects using Level 4 solutions for design and engineering integration (IoT Analytics).

These implementations are translating into measurable business results across industries. In automotive, Mercedes-Benz shifted from physical to digital durability testing using ISA-95–aligned digital twins, transforming its engineering process from prototyping to CAE simulation. BMW deployed collaborative robots at its Steyr engine plant, eliminating unplanned downtime during changeovers by properly integrating Level 0–1 systems (IoT Analytics).

The pharmaceutical and food sectors are seeing similarly strong outcomes. Takeda Pharmaceuticals implemented EcoStruxure Building Operation with the AVEVA System Platform and Modicon controllers, achieving a 15% energy surplus while boosting efficiency. In food manufacturing, OWS Foods deployed Rockwell's Plex Supply Chain Planning (SCP) aligned with ISA-95, improving forecasting accuracy by 25% and reducing customer lead times by 33% (IoT Analytics). Together, these cases illustrate how ISA-95 alignment enables both operational excellence and rapid ROI.

Broader survey data reinforces these results. According to the ARC Advisory Group, MES implementations aligned with ISA-95 deliver returns greater than 50% across surveyed applications. The critical success factor lies in combining organizational, process, and technology changes, not technology deployment alone. Manufacturers that attempt technology-first implementations without the ISA-95 framework face correction costs 100–300 times higher than those who invest in proper upfront design (ASM Events Online). This stark cost differential underscores why ISA-95 compliance remains essential even as manufacturers embrace next-generation technologies.

Integration Challenges Require Sophisticated Architectural Solutions

The practical challenge of connecting enterprise resource planning (ERP) systems at Level 4 with manufacturing execution systems (MES) at Level 3 remains one of the most complex aspects of ISA-95 implementation (International Society of Automation). These systems operate on fundamentally different time scales: ERP typically runs on daily or weekly planning cycles, while MES requires response times measured in minutes or seconds. This temporal mismatch creates significant integration hurdles that must be addressed with carefully designed architectures.

Figure 1: ISA-95 Layered Architecture

Modern solutions rely on multiple integration patterns to bridge these gaps. Message queuing platforms such as Apache Kafka have become a preferred option, supporting event-driven architectures with publish–subscribe models that enable asynchronous processing, fault tolerance, and scalability. Enterprise-grade platforms like SAP Manufacturing Integration and Intelligence (SAP MII) provide a dedicated layer between SAP ERP and shop floor systems, supporting multiple protocols (OPC UA, RFC, IDoc, MQTT) and delivering business logic services for complex transformations while maintaining quality-of-service features essential in manufacturing environments.

Integrating SCADA protocols into event-driven architectures introduces further complexity, especially in modern IIoT deployments. Many manufacturers address this through protocol gateways that normalize diverse inputs—OPC UA from new equipment, Modbus TCP from legacy PLCs, and MQTT from edge devices—into unified data streams.

Architectures built on Ignition SCADA with Kepware OPC Server are common, enabling hierarchical tag organization aligned with ISA-95 equipment models and supporting real-time alarm pipelines with MQTT notifications. Edge computing platforms such as Azure IoT Edge further strengthen this approach by providing local protocol conversion and store-and-forward capabilities to ensure data integrity during network disruptions.

Finally, many organizations are extending ISA-95 concepts through custom type systems and abstractions to support modern architectural patterns while preserving standards compliance. For example, GraphQL schemas mapping ISA-95’s equipment hierarchy (Enterprise → Site → Area → Work Center → Work Unit) provide a flexible integration model for modern applications.

Manufacturers are implementing these abstractions within microservices architectures, where equipment services manage the physical hierarchy, material services handle inventory and lots, personnel services oversee qualifications and assignments, and production services coordinate jobs and performance metrics. Open-source projects such as B2MML.NET (providing C# libraries for ISA-95 XML schemas with JSON serialization) and commercial platforms like Tulip enable rapid development of standards-compliant, modular solutions.

Balancing Operational Continuity with Cyber Resilience

Network security in ISA-95 environments requires a fundamentally different approach than traditional IT security, as recent high-profile incidents have demonstrated (NIST CSRC). The Colonial Pipeline attack in May 2021, which disrupted 45% of East Coast fuel supply for six days, stemmed from a compromised VPN account without multi-factor authentication and inadequate segmentation between IT and OT networks. Similarly, the JBS ransomware attack, which disrupted global meat processing operations, exposed weaknesses in OT/IT convergence (CPO Magazine). These incidents accelerated security investments across American manufacturing, driving adoption of enhanced network segmentation, mandatory MFA for remote access, and air-gapped backup systems.

VLAN segmentation aligned with ISA-95 levels provides the foundation for secure manufacturing networks. Best practice calls for dedicated VLANs for each level:

Levels 0–1 for process control and sensing devices (with safety systems air-gapped when possible)

Level 2 for supervisory control including SCADA and HMI

Level 3 for manufacturing operations management including MES

Level 4 for enterprise business systems

The most critical boundary lies between Levels 3 and 4, where an Industrial Demilitarized Zone (IDMZ) with dual-firewall architecture separates IT and OT networks, and application servers in the DMZ provide controlled, secure data exchange (ISA).

Modern tools extend this model with software-defined networking (SDN), enabling dynamic segmentation based on operational needs. Cisco TrustSec applies Security Group Tags (SGTs) with policy enforcement through SGACLs, while VMware NSX delivers micro-segmentation at the hypervisor layer with distributed firewalls (Cisco).

Together, these technologies support zero-trust architectures adapted for OT. Maturity typically progresses in phases: establishing the foundation (6–12 months) with asset inventory and basic segmentation, enhancing security (12–24 months) with advanced threat detection and privileged access management, and optimizing (24–36 months) with machine learning-based anomaly detection and automated response.

OT security challenges also extend beyond network design to day-to-day operations. Patch management is particularly difficult when production systems cannot be easily taken offline, updates require extensive testing, or vendors provide limited support for legacy assets (Verve Industrial). Manufacturers address these realities through structured processes covering asset discovery, vulnerability prioritization, patch validation, isolated testing, coordinated deployment, and compliance documentation (Rockwell Automation).

Standards Comparison Reveals Complementary Frameworks

The relationship between ANSI/ISA-95 and IEC/ISO 62264 represents international harmonization rather than competition, with IEC 62264 derived directly from ANSI/ISA-95. Both standards define an identical five-level hierarchy and consistent functional frameworks, though regional differences influence implementation (Automation.com).

In the U.S., manufacturers typically adopt the full eight-part ISA-95 suite, often in conjunction with MESA International guidelines and B2MML XML implementations. In Europe, IEC 62264 is more commonly integrated with the Reference Architecture Model Industry 4.0 (RAMI 4.0) and harmonized with related IEC standards such as IEC 61512 for batch control and IEC 62443 for cybersecurity.

The latest ANSI/ISA-95.00.01-2025 revision reflects emerging digital transformation requirements not yet fully incorporated into IEC 62264. Key updates include support for modular architectures with container-based deployments, enhanced metadata capabilities for data-centric design, and improved mechanisms for IT/OT convergence (International Society of Automation). These changes mark a shift from traditional pyramid-style architectures toward more flexible network-based structures that enable Industry 4.0 integration while preserving ISA-95’s established functional definitions and compliance requirements.

Smart Manufacturing Trends Reshape but Don't Replace ISA-95

Digital twin implementations leveraging ISA-95 models represent one of the most transformative trends in modern manufacturing. According to McKinsey, 86% of manufacturing executives see digital twin applications in their organizations, with 44% already implementing them. These solutions integrate across ISA-95 levels:

Real-time sensor data from Levels 0–2

MES integration at Level 3 for production optimization

ERP integration at Level 4 for demand forecasting

Manufacturers adopting digital twins report development time reductions of up to 50% and monthly cost savings of 5–7% (McKinsey).

Artificial intelligence and machine learning applications similarly align with ISA-95’s hierarchical structure while extending its capabilities:

At Level 2, AI supports predictive maintenance and automated quality control.

At Level 3, it enables production optimization and scheduling improvements.

At Level 4, AI powers demand forecasting and supply chain optimization.

The World Economic Forum’s 2024 research shows these applications can boost labor productivity by 50% through augmentation rather than replacement, directly addressing the 71% of manufacturers who cite talent retention as their top challenge.

Edge computing and 5G connectivity are further reshaping ISA-95 implementations by enabling fast-response activities at the device level while maintaining compliance with standards. This evolution supports real-time data synchronization across ISA-95 levels, improves IIoT connectivity, and enhances mobile workforce capabilities (Automation.com). Cloud platforms complement this model by providing scalable storage and computational power for big data processing, while hybrid approaches remain common as manufacturers balance cloud benefits with operational security requirements (ISA).

Balancing Compliance with Innovation

Organizations face important decisions about when to follow ISA-95 strictly and when to adapt it to fit their specific needs. Strict adherence is essential in environments where regulatory compliance is non-negotiable—such as FDA-regulated pharmaceuticals and aerospace manufacturing. It also proves critical for multi-site operations that require consistent information exchange, ERP–MES integration projects where standard interfaces lower costs, and legacy modernization programs where ISA-95 provides a structured migration pathway. In these scenarios, the framework’s stability and strong vendor support ecosystem deliver clear advantages.

Flexible adaptation, on the other hand, is often more effective in contexts that demand agility. Industry 4.0 pilot projects benefit from looser interpretation to enable rapid innovation, while smaller operations may find full implementation unnecessarily complex. Emerging technologies such as AI and advanced analytics frequently call for hybrid approaches, and startup manufacturers with limited legacy constraints often prioritize speed over strict conformity. The key is to preserve ISA-95’s core information models to ensure interoperability, while adopting modern architectural patterns like microservices and cloud-native deployments (ISA).

Industry context also shapes implementation strategies. Discrete manufacturing typically allows greater flexibility at Level 3, with emphasis on real-time scheduling and PLM integration. Process industries require stricter adherence to support regulatory demands, traceability, and optimization through digital twins. Life sciences manufacturers face the strictest requirements, including CFR 21 Part 11 and EU GMP compliance, necessitating detailed documentation and integration with LIMS and quality management systems.

Scalability further highlights ISA-95’s adaptability. Small and mid-sized enterprises often begin with phased adoption—focusing on Level 3–4 integration, leveraging cloud-based SaaS platforms, and prioritizing core information exchange. Large enterprises, in contrast, typically pursue full eight-part implementations, global harmonization between ANSI/ISA-95 and IEC 62264, and integration with enterprise-wide digital transformation initiatives. This flexibility underscores ISA-95’s value as both a compliance framework and a foundation for innovation across the manufacturing spectrum (ISA).

Conclusion

ISA-95 provides a critical framework for American manufacturing’s digital transformation, enabling organizations to integrate Industry 4.0 technologies while preserving operational integrity and regulatory compliance (ISA). Its proven ability to deliver ROI in the range of 50–300% through structured implementation, combined with updates in the 2025 revision to support containerized architectures and data-centric systems, positions ISA-95 as a cornerstone for modern IT/OT integration.

Real success, however, requires a pragmatic approach. Manufacturers must maintain core ISA-95 compliance to ensure interoperability, while allowing flexibility when adopting emerging technologies (Automation World). This means investing in robust security architectures to address OT/IT convergence risks, using phased migration strategies to balance continuity with transformation goals, and developing a workforce that can bridge both traditional automation and digital technologies (TechTarget). With industrial software and OT hardware spending projected to exceed $350 billion by 2030 (IoT Analytics), ISA-95 will remain as a compelling and unifying framework for guiding these investments.

The convergence of ISA-95 with Industry 4.0 capabilities demonstrates that standards accelerate, rather than limit, innovation. Digital twins are reducing development times by as much as 50%, AI-augmented systems are boosting productivity by 50%, and edge computing is enabling real-time optimization (McKinsey, World Economic Forum). Manufacturers that strategically implement ISA-95 in this context will not only achieve operational excellence, but also build resilient, adaptive production systems prepared for the challenges ahead.