For years, manufacturers have lived with a digital disconnect: ERP systems designed for structure and control on one side, shop floor systems optimized for speed and precision on the other. Both are critical. But together? Well, they’ve never quite spoken the same language.

The result has been decades of workarounds. We’re talking about custom integrations, middleware toolkits, and armies of operators acting as “human APIs” with clipboards in hand. These patches may have kept production moving, but they’ve rarely delivered what leaders are really after — a seamless, real-time flow of information that unites the business and the shop floor into one connected enterprise.

Now, with the rise of real-time data platforms, AI, and modern integration standards, there’s a smarter path forward building upon data fabric architectures. By rethinking the connective tissue between ERP, MES, and plant-floor systems, manufacturers can finally bridge this divide and establish a foundation for agility, intelligence, and long-term ERP modernization.

If you’d like to see how this works in detail, we’ve put together a whitepaper that breaks it all down — from integration challenges to practical strategies for building a digital nervous system across your enterprise. Click here to download the full whitepaper and explore how a data fabric can help your organization move from workarounds to a smarter, more sustainable way of connecting operations.

A New Foundation for Smart Manufacturing

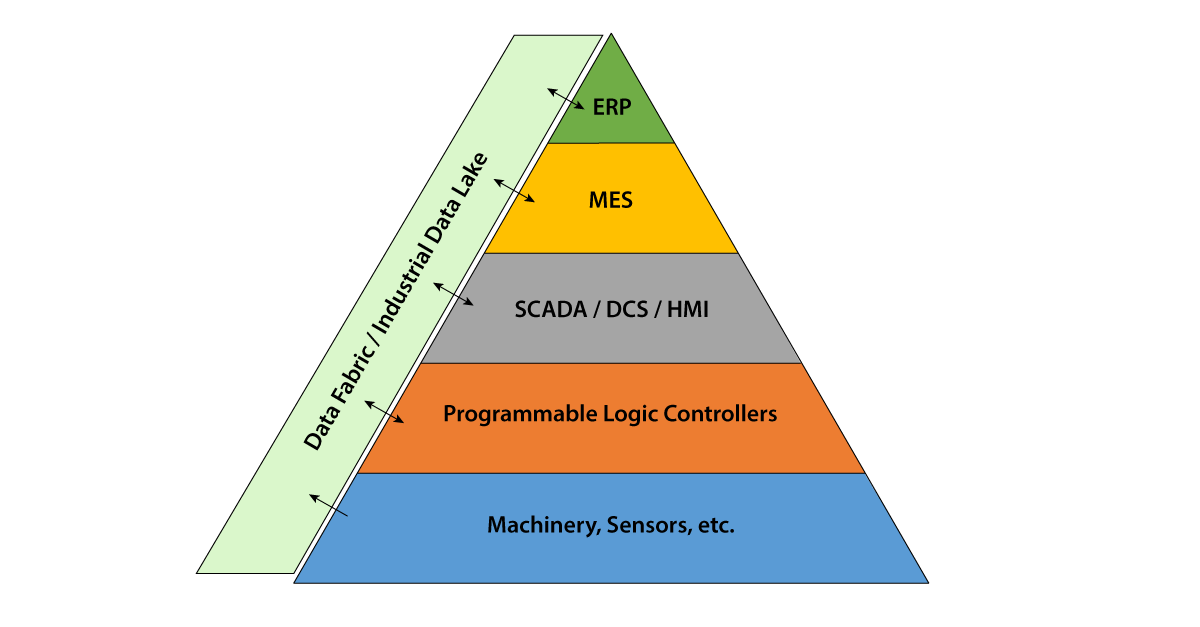

Figure 1 below illustrates the positioning of a data fabric within the context of the classic ISA-95 reference architecture. Rather than forcing ERP and MES/SCADA platforms into brittle, point-to-point conversations, a data fabric introduces a common, governed foundation where information can be harmonized, enriched, and shared across the enterprise.

Figure 1: Streamlining Data Integration Using a Data Fabric Architecture

Of course, this isn’t just about solving integration headaches. It’s about reimagining the way that your organization thinks about data itself — not as a byproduct of operations, but as a strategic asset that can drive resilience, agility, and innovation.

Logically, a data fabric acts as the connective tissue that allows every system, from ERP to the shop floor, to plug into the same information backbone. That unlocks four critical capabilities:

Simplified Integration: By supporting a wide range of industrial protocols and formats through plug-and-play connectors, the fabric abstracts away technical complexity and shortens deployment timelines.

Reusable Data Models: Instead of reinventing the wheel with every integration, organizations can standardize on common data objects like work orders, equipment status, or bills of material — creating consistency that scales across plants and geographies.

API-Powered Democratization: Clean, standardized data products are exposed through APIs, making them accessible not just to IT, but to developers, partners, and even frontline workers who need actionable insights.

Real-Time Intelligence: With event streams flowing through the fabric, manufacturers can sense and respond in the moment — adjusting production processes, triggering maintenance, or flagging anomalies before they become bottlenecks.

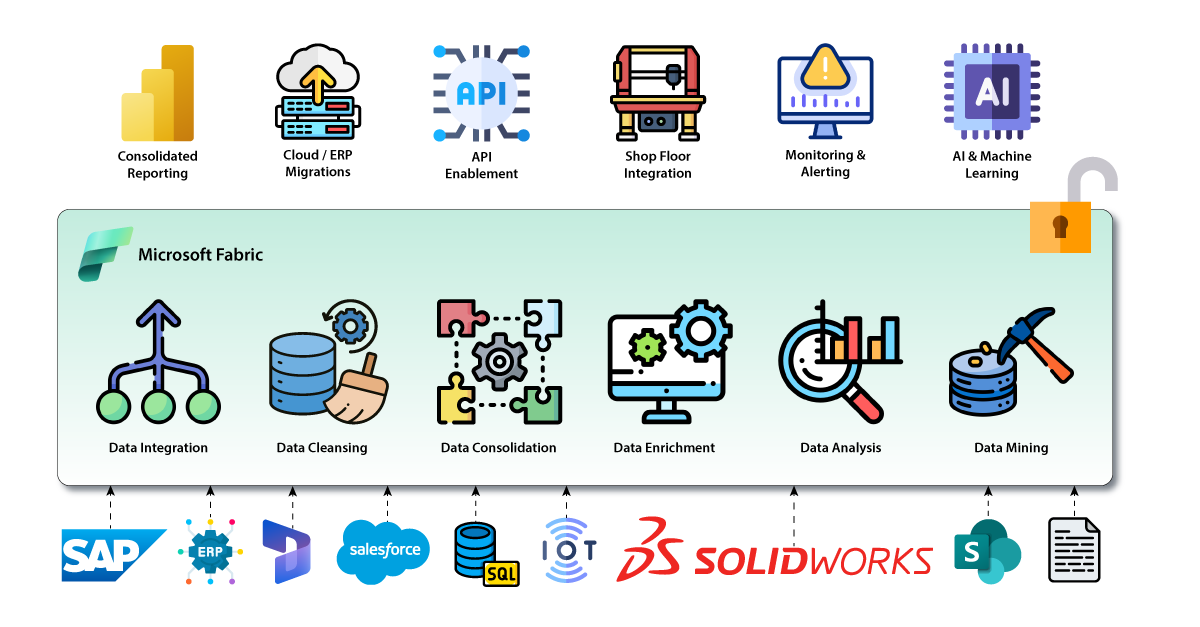

Figure 2: Building a Data and Integration Backbone Using a Data Fabric Architecture

Taken together, these capabilities make the enterprise more adaptive. They provide a foundation where innovation is no longer a disruptive event but an ongoing process where adding a new system, piloting AI, or experimenting with a new reporting tool doesn’t require ripping apart the old integration landscape.

In short, a data fabric isn’t just a technical fix; it’s a strategic enabler that turns connectivity into competitive advantage.

From Integration Spaghetti to Strategic Agility

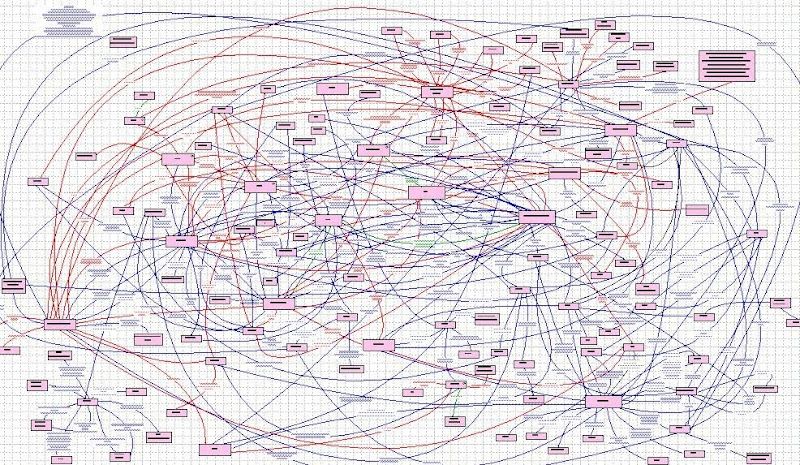

Manufacturing landscapes have become more complex, not less. Every new plant, piece of equipment, or business application adds another layer of connectivity to manage. Over time, these connections accumulate into an integration web that looks less like a well-structured architecture and more like a plate of spaghetti: tangled, fragile, and nearly impossible to scale without risk.

Figure 3: Integration Spaghetti - A Cautionary Tale

This complexity isn’t just a technical nuisance; it’s a barrier to progress. When every new initiative requires weeks (or months) of custom integration, innovation slows. Pilot projects stall out because scaling them enterprise-wide feels too expensive or disruptive. ERP upgrades drag on for years because the integration map is too brittle to touch. In short, complexity becomes the tax manufacturers pay for every ounce of progress.

A data fabric flips the equation. Instead of every system connecting to every other system, each connects once to the fabric. That simple architectural shift has powerful consequences:

Complexity is contained. Systems plug into a common foundation rather than multiplying point-to-point connections.

Innovation becomes scalable. A pilot program in one plant doesn’t require re-engineering when rolled out globally; the underlying data models and APIs are already in place.

Modernization is sustainable. Whether upgrading ERP, introducing digital twins, or deploying AI-driven analytics, new capabilities can be layered in without unraveling existing systems.

And here’s where it becomes a true source of competitive advantage. With integration simplified, you can move faster than any of your competitors that are weighed down by legacy architectures. You can bring new products to market more quickly, adapt to supply chain disruptions with greater resilience, and scale digital initiatives without the constant fear of breaking what already works.

In short, the data fabric turns complexity from a liability into an asset, transforming the integration challenge into a strategic foundation for speed, adaptability, and long-term growth.

Building a Digital Nervous System

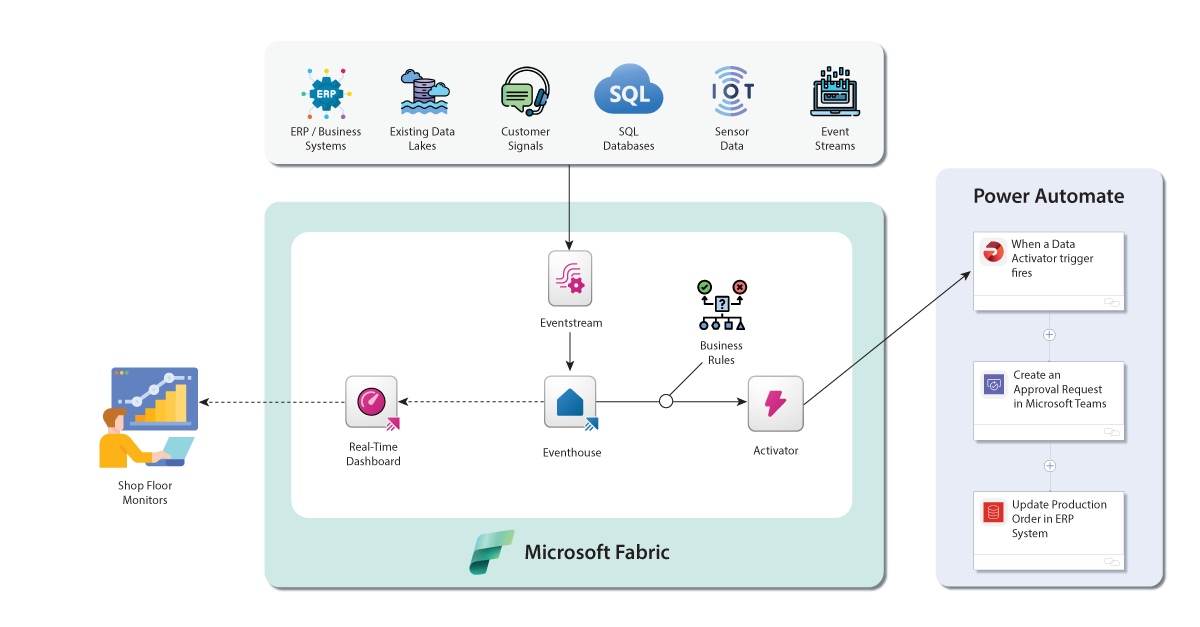

Of course, solving integration challenges is just the first step. With real-time event streams running through the data fabric, you can establish what amounts to a digital nervous system within your enterprise. Just like human nervous systems, this digital nervous system operates as a dynamic layer that senses what’s happening on the shop floor (and beyond) and coordinates immediate responses across the enterprise.

Just as the human body reacts to stimuli without conscious thought, a data fabric embeds intelligence directly into your operations. A temperature spike in a critical machine doesn’t just get logged for future review; it triggers a preventative maintenance workflow before downtime occurs. A deviation in product quality isn’t buried in a batch report; it automatically adjusts process parameters or alerts supervisors to intervene.

Figure 4: Building a Digital Nervous System Using Fabric Real-Time Intelligence

In this scenario, the business doesn’t just record what happened, it adapts in the moment. That shift from reactive reporting to proactive response is transformative. Instead of discovering yesterday’s problems in today’s dashboards, manufacturers operate with continuous awareness and agility.

This kind of nervous system also scales beyond the four walls of the plant. Event streams can be extended to supply chain partners, logistics providers, or even customers, creating an environment where the entire ecosystem can sense and respond to change together. A supplier delay might automatically adjust production schedules. A sudden demand surge could trigger shifts in staffing or inventory allocation.

By embedding intelligence into the very flow of data, you can unlock a new level of resilience and adaptability within your organization. It’s not about digitizing the old ways of working; it’s about creating a connected enterprise that can see, decide, and act with the speed of the shop floor and the intelligence of the back office.

Paving the Way for Composable ERP

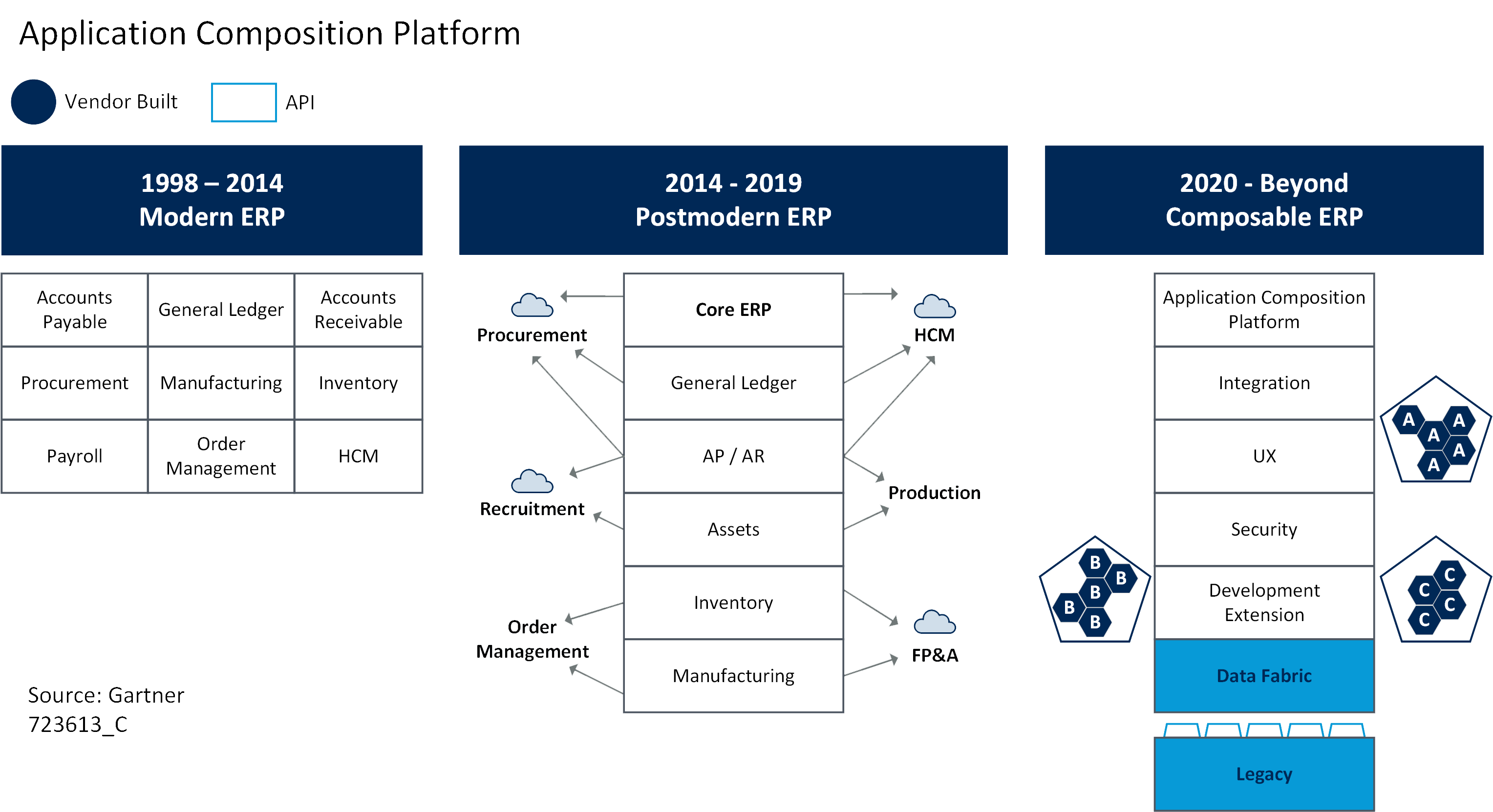

Zooming out a bit, these concepts also align very nicely with the industry's shift towards composable ERP. If your organization is in the early stages of an ERP upgrade evaluation, it's worth noting that the days of monolithic, one-size-fits-all ERP suites are ending.

For decades, manufacturers were told to choose a single platform that could “do it all,” even though no ERP vendor was ever best at everything. The result was often compromise: strong financials paired with weak manufacturing support, or powerful planning tools locked inside systems that were too rigid to evolve.

Forward-looking manufacturers are moving away from this all-or-nothing approach. Instead, they are embracing modular, best-of-breed strategies — selecting the right tool for each job while still maintaining a coherent enterprise backbone. A global enterprise might continue running a legacy ERP at the core while adopting a SaaS-based procurement solution, a specialized quality management platform, or advanced analytics in the cloud. This flexibility allows business units to innovate at their own pace while still contributing to a unified enterprise strategy.

Figure 5: Moving Towards Composable ERP Architecture - ©Gartner

As you can see in Figure 5, the data fabric is the glue that makes this composable model work. It provides the common data foundation that allows legacy ERP systems, modern SaaS applications, and plant-floor platforms to coexist in harmony. It enables clean-core migrations by separating integration logic and data models from the ERP itself, so you don’t need to overload the core with customizations. It allows innovation to be layered around the edges without disrupting critical operations.

Most importantly, it changes the economics of ERP transformation. Instead of waiting years for a massive upgrade to deliver business value, you can deliver results on a continuous basis. A new reporting capability here and an AI-driven predictive model there, each improvement plugs into the fabric, benefits from clean and consistent data, and scales across the business without requiring wholesale system replacement.

In this way, composable ERP supported by a data fabric becomes more than a technology strategy. It’s a business model for adaptability, where you can evolve in smaller, safer steps while still moving decisively toward a modern, intelligent future.

Closing Thoughts

These days, you don’t just need systems that connect; you need systems that can evolve. Point-to-point integrations or middleware kits might solve today’s problem, but they often create tomorrow’s technical debt. What’s needed is an approach that not only connects ERP and shop floor systems but also anticipates change, embraces new technologies, and supports growth over the long term.

A data fabric delivers exactly that. It does more than bridge ERP and the shop floor. It establishes a foundation for agility, intelligence, and modernization that grows with the business. By harmonizing data and embedding real-time responsiveness into operations, it creates an enterprise that can sense, decide, and act with speed and precision.

This matters because the pace of change in manufacturing has never been faster. Market demand shifts overnight, supply chains face constant disruption, and new technologies like AI, digital twins, and autonomous systems are rapidly reshaping the competitive landscape. Companies that cling to rigid, monolithic systems will find themselves outpaced. Those that build on a data fabric will be able to adapt, scale, and thrive no matter what the future holds.

In a world where change is the only constant, the data fabric is more than an integration strategy. It's a strategic backbone for continuous innovation. It's also the architecture that ensures your business stays resilient, competitive, and ready for whatever comes next.