Despite significant investments in AI and digital technology, it's surprising how much shop floor execution continues to rely on paper printouts, handwritten notes, and manual task processing. This phenomenon seems to apply regardless of whether the customer is running a legacy ERP system or the latest and greatest.

One of the primary reasons for this is that ERP systems focus first and foremost on capturing transactions, which leaves gaps when it comes to supporting the dynamic realities of the shop floor. ERP systems do an excellent job of planning and scheduling production runs on the front end, and they’re reliable for capturing results and inventory movements on the back end. But in the middle — where operators and technicians are actually executing semi-structured production tasks — there’s a pretty wide functional gap.

The reality is that ERP systems were never designed or optimized to guide operators in real time. Instead, the expectation is that workers remain in constant communication with the system to record results and see what’s going on. The system doesn’t proactively come to them, leaving operators largely on their own to keep production moving.

While it's easy to criticize ERP vendors for perceived shortcomings, the reality is that these types of problems call for a different type of software solution, one that's tailored to the unique requirements of modern manufacturers. These software solutions go under the heading of manufacturing execution system (MES) or, in some cases, manufacturing operations management system (MOM).

Even though MES systems have been around for a long time, it's somewhat surprising how often we find manufacturers trying to get by with the functionality built into their ERP system. With that in mind, in this article we’ll take a closer look at seven key benefits of adopting an MES system and how these systems can help you close that execution gap.

From improving quality and compliance to boosting efficiency and laying the foundation for smart manufacturing, an MES system could be the missing link you've been looking for.

1) A Foundation for Smart Manufacturing

In the past 15 years or so, you've no doubt heard a lot of talk about Industry 4.0 and the technologies that power it:

Industrial Internet of Things (IIoT) & Digital Twins

Automation & Robotics

Artificial Intelligence (AI) & Machine Learning (ML)

Cloud & Edge Computing

Augmented Reality (AR) / Virtual Reality (VR)

5G Networking

Additive Manufacturing & 3D Printing

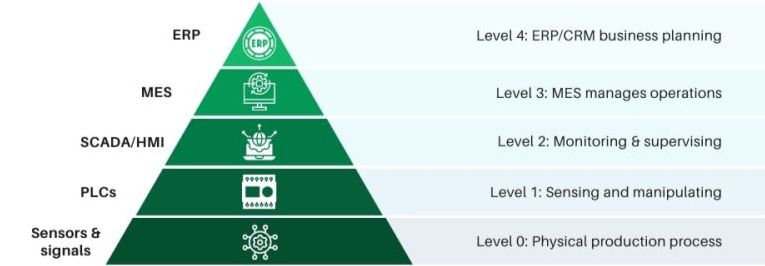

Successful integration of all these technologies calls for a layered architecture like the one prescribed in the ISA-95 standard. As you can see in Figure 1 below, MES systems are strategically positioned between ERP systems and lower-level control systems and sensor devices. In a very literal sense, you can think of MES systems as a connectivity layer for the shop floor (and beyond).

Figure 1: Positioning of MES Systems in the ISA-95 Standard Pyramid

Unlike ERP systems where the focus is more on application integration, MES systems offer much better support for the lower-level protocols utilized by machines and equipment on the shop floor. As such they provide an excellent foundation for smart manufacturing, enabling automation, IoT, and advanced analytics to future-proof your operations.

Bottom line: if many of your execution struggles stem from a lack of connectivity, then an MES system is likely a missing piece to the puzzle.

2) Real-Time Visibility

One of the core principles of lean manufacturing is to establish a smooth, uninterrupted “flow” through every process. Much like a river or stream, product flow is hindered by obstacles — whether they appear as rocks, sharp bends, or full-scale dams. Whenever we clear those obstacles, it becomes much easier to eliminate waste, whether that’s piles of work-in-process (WIP) inventory, machines sitting idle, or a host of other production-related issues.

MES systems make it easier to remove obstacles by providing controllers with real-time visibility into how machines, people, and materials are working together. Instead of having to wait on spreadsheets or end-of-shift reports, managers can rely on alerts and dashboards like the one depicted in Figure 2 below to see what’s happening on the shop floor and act accordingly to make sure that the entire production environment stays in sync.

Figure 2: Production Monitoring Dashboard in Rockwell Automation's Plex MES

3) Efficiency Gains & Cost Savings

While most ERP systems provide support for recording the results of production processes, many important details tend to get lost in translation. This is especially true whenever execution results are initially recorded on paper forms as these forms can get easily become misplaced, copied incorrectly, or sit in a stack until someone has time to enter the data.

Without strong system support, other important production details might also go unnoticed:

The actual time spent on a production task may be rounded up or forgotten altogether when workers submit labor confirmations at the end of a shift.

The wrong component parts may be (continually) pulled from inventory.

Details about excessive scrap or material waste might not get recorded.

Inventory updates might be delayed or missed entirely.

Inspection or defect results may be omitted, causing larger-scale issues to go undetected/untreated.

These gaps ultimately result in wasted time, higher costs, and managerial decisions based on incomplete information. MES systems address these problems head-on by making it easier to capture these details directly on the shop floor, in real time. Plus, with built-in decision support, operators are guided to select the right parts and quality checks are recorded instantly within the flow of work. This level of precision ensures that material usage, labor hours, and production outputs are all tracked accurately.

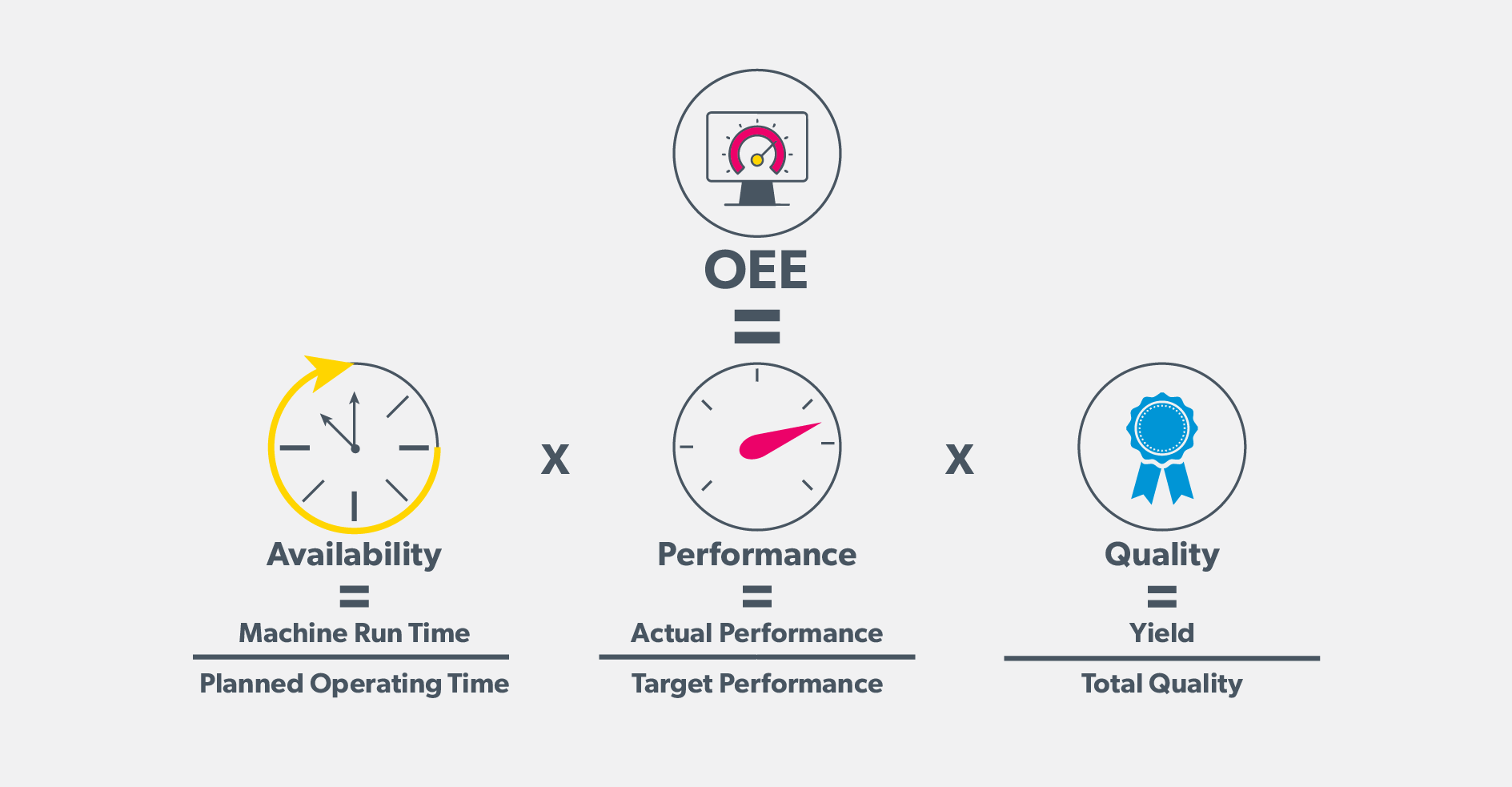

Figure 3: Measuring Efficiency with OEE

The result is less waste, tighter control of resources, and more efficient operations across the plant. By replacing guesswork and after-the-fact reporting with real-time visibility, MES systems empower you to lower costs and continuously improve performance.

4) Smarter Scheduling & Asset Utilization

A highly experienced production manager once told me that the detailed production plans put together by his company's ERP system usually blew up a few hours into the work week. On paper, everything looked perfect. Machines were loaded, labor was allocated, and materials were available. But reality has a way of interfering. A key operator calls in sick. A machine goes down unexpectedly. A rush order comes in from a major customer. Suddenly, the plan no longer matches what’s happening on the shop floor.

High-end ERP systems offer incredibly advanced production planning capabilities. They excel at creating optimized schedules based on forecasts, resource availability, and customer demand. But ERP systems lack the real-time visibility needed to pivot quickly when conditions change. Without a finger on the pulse of the shop floor, even the best plan can unravel fast.

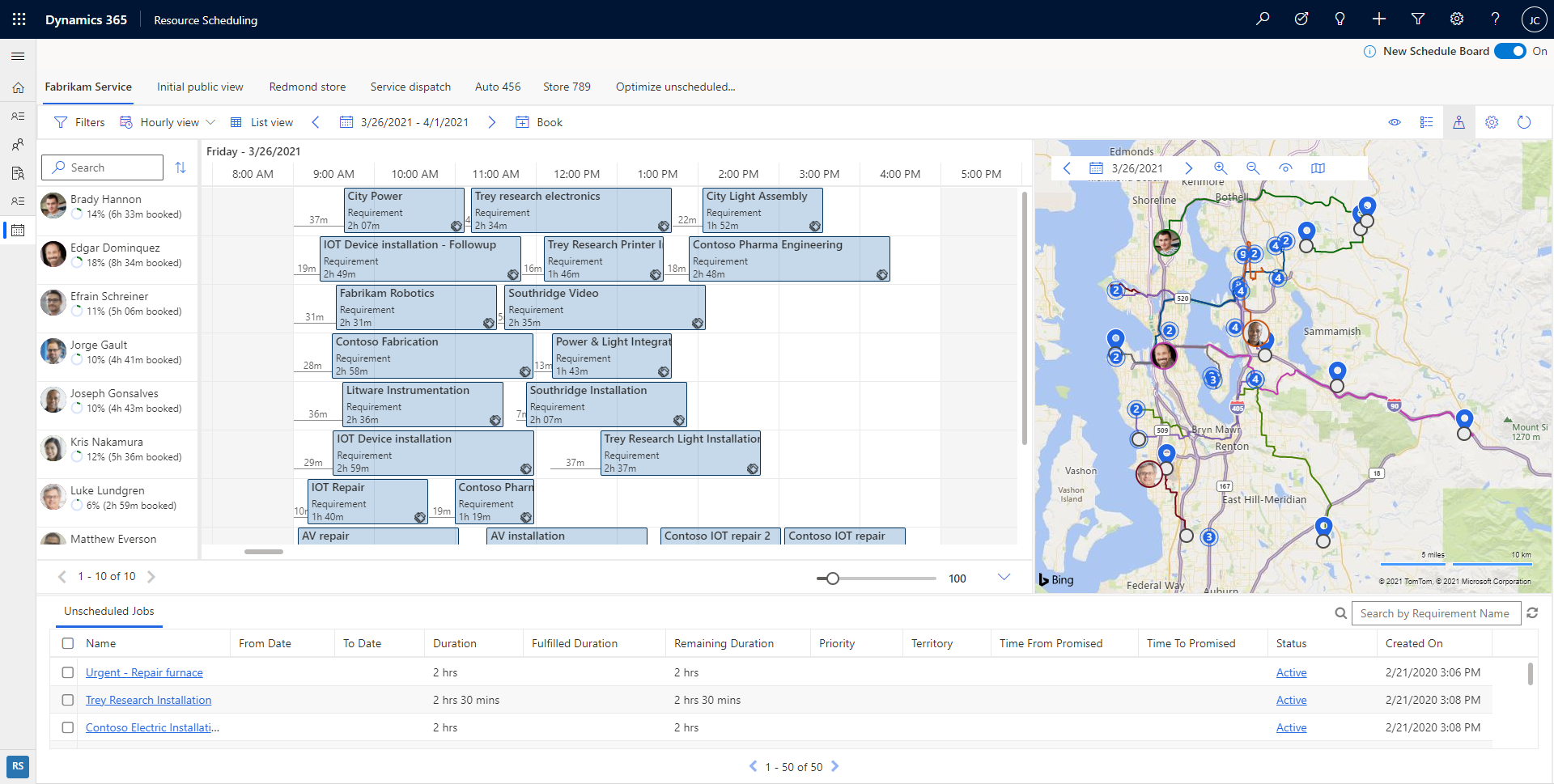

This is another area where MES systems really shine. Since MES systems capture live data from machines, materials, and operators, we're able to plan production runs with much more precision. Most MES systems also enable you to run “what-if” scenarios to explore the impact of changes such as adding an extra shift, rerouting jobs to a different work center, or delaying a lower-priority order. Finally, since MES systems support predictive maintenance, we can anticipate equipment issues before they cause downtime, ensuring that machines are available when you need them most.

Figure 4: Maintenance Scheduling with Dynamics 365

The result is a production schedule that isn’t just theoretically optimal but practically executable. By bridging the gap between ERP planning and real-world execution, MES helps you keep resources fully utilized, reduce downtime, and meet customer commitments more reliably.

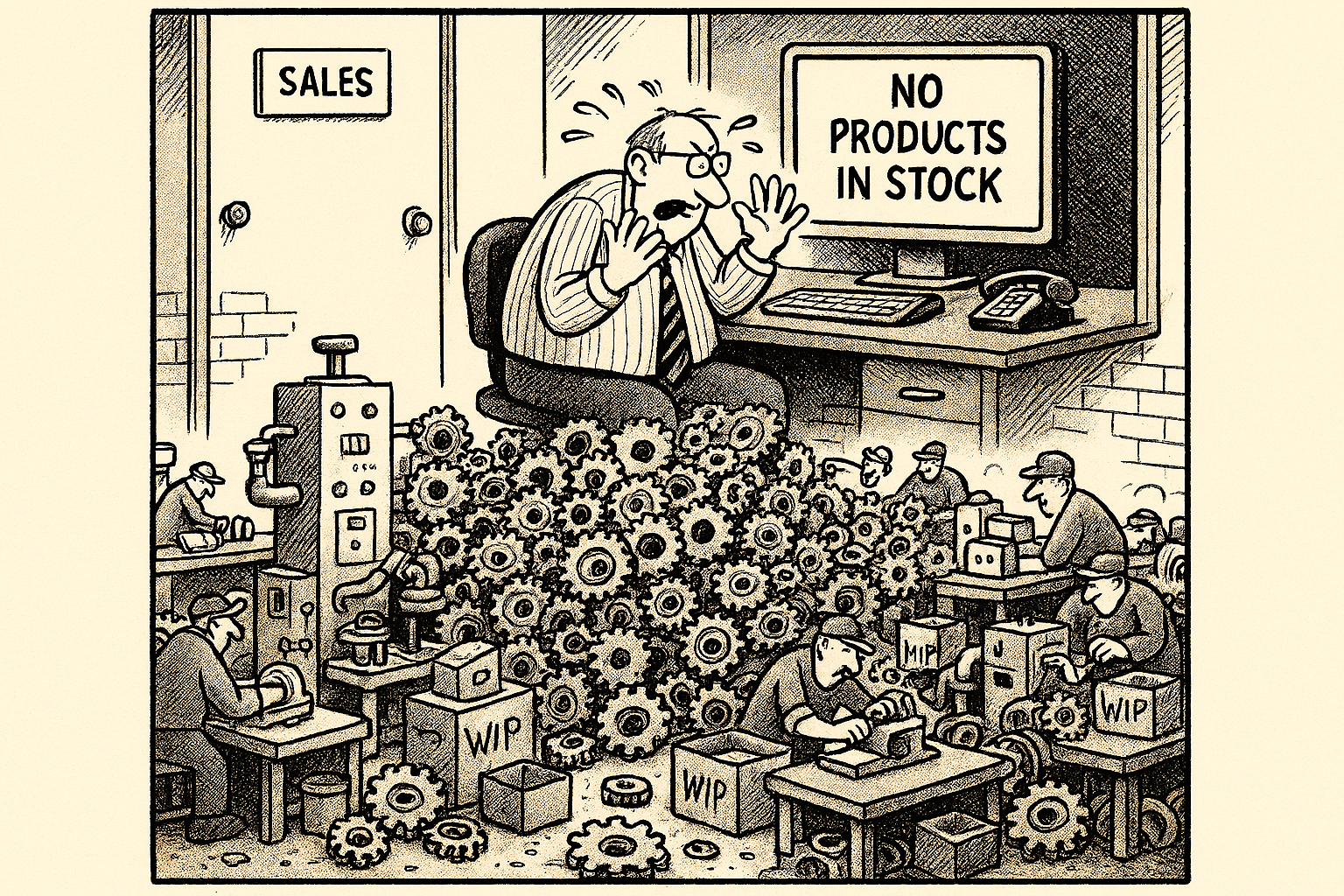

5) Stronger Supply Chain Collaboration

This is another one of those areas where an MES system shares overlapping functionality with an ERP system. While most ERP systems typically "own" these core processes, they're only as good as the data they have to work with. For example, if material movements on the shop floor are delayed in getting recorded, the system may think stock is still available when it’s already been consumed, or it may trigger unnecessary reorders because it doesn’t recognize what’s actually on hand. The result is confusion, excess inventory, or, in the worst case, production stoppages when critical materials aren’t where they need to be.

MES systems help close this gap by tracking goods movements in real time. Every material issued to production, every component consumed, and every finished part produced can be logged automatically. This creates an accurate, up-to-the-minute picture of inventory and makes it easier to coordinate procurement activities, plan replenishments, and avoid both shortages and overstock situations.

Figure 5: The Perils of Mismanaged Production Inventory

It's also worth noting that these benefits don’t stop at the four walls of the factory. With accurate MES data feeding into ERP and supply chain systems, suppliers can collaborate more effectively, aligning their deliveries with actual consumption and production needs. This reduces lead times, minimizes carrying costs, and ensures that the right materials are available to keep operations running smoothly.

In short, MES brings the real-time execution data that supply chain systems need to function at their best, making collaboration across the entire value chain more reliable and efficient.

6) End-to-End Traceability

We’ve already highlighted real-time visibility as one of the key benefits of an MES. Traceability takes this a step further by allowing you to retrace every step of production, almost like traveling back in time to see exactly how a product was made. When integrated properly, MES systems unlock an ability to create a complete digital thread that connects raw materials, in-process steps, and finished goods into a single, auditable record.

This digital thread pays dividends in several ways. If a quality issue surfaces, you can quickly trace it back to the exact batch of raw materials, the specific machine used, or even the operator on shift at the time. That means faster root-cause analysis, quicker and more targeted recalls, and ultimately less risk to your brand. Beyond compliance and customer assurance, the same audit trail helps you carefully analyze performance, pinpoint recurring bottlenecks, and identify areas where processes can be streamlined or improved.

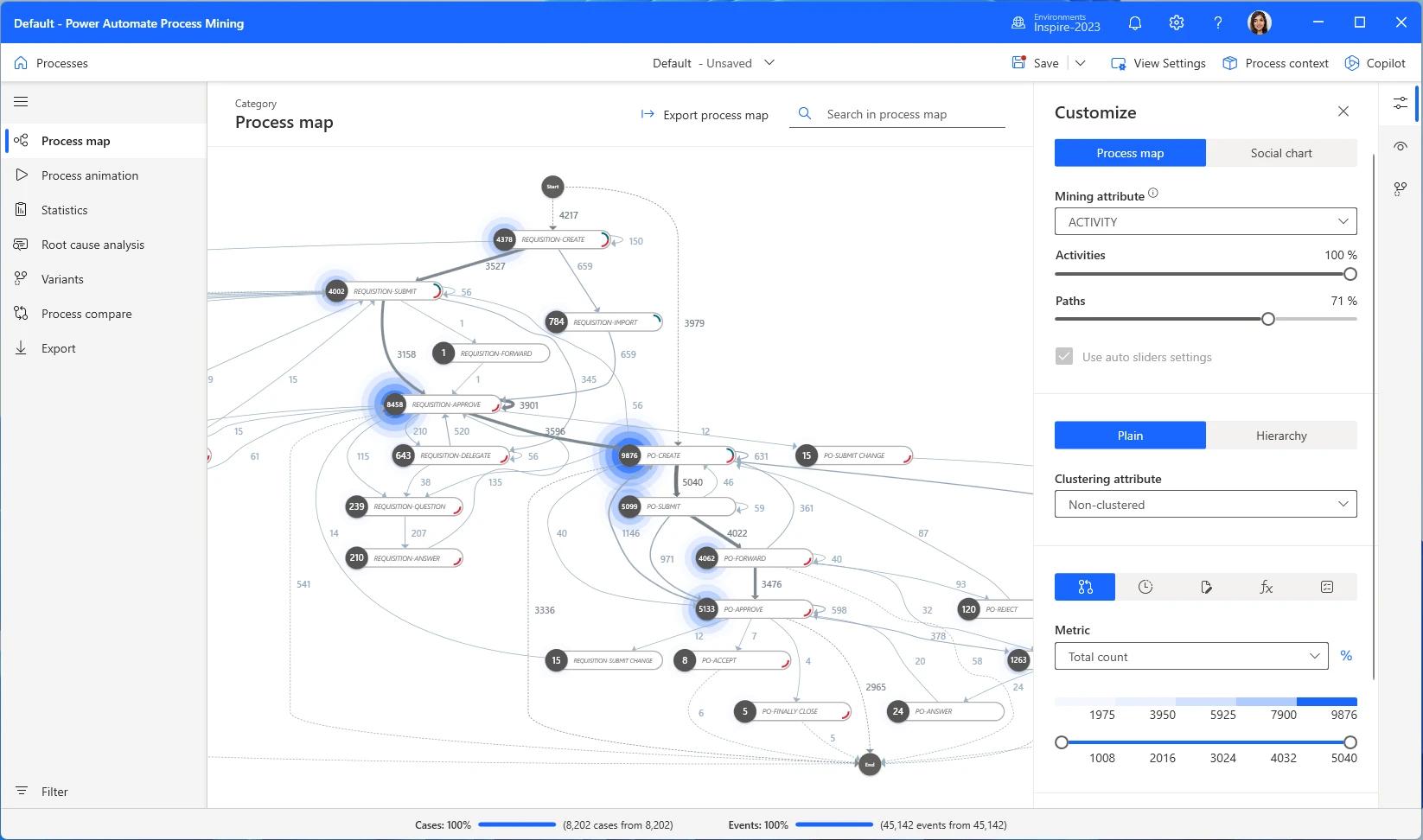

Figure 6: Analyzing Process Performance with Power Automate Process Mining

Consider the food and beverage industry. If a contaminated ingredient is discovered, an MES allows you to instantly see which batches were affected, which customers received them, and which products need to be pulled from shelves. Without that level of detail, the recall might have to be much broader, costing more time, money, and reputation than necessary. Automotive suppliers face a similar challenge, often needing to provide precise component history during customer audits. With MES, that documentation is readily available and backed by reliable data.

In an industry where trust and efficiency are everything, end-to-end traceability ensures you’re not relying on guesswork or paper trails. Instead, you have a clear, verifiable record that supports both operational excellence and customer confidence.

7) Better Quality & Compliance

Quality is the cornerstone of customer trust and long-term success. However, in practice, we find that many customers don't invest enough time and energy into building out a robust quality management process.

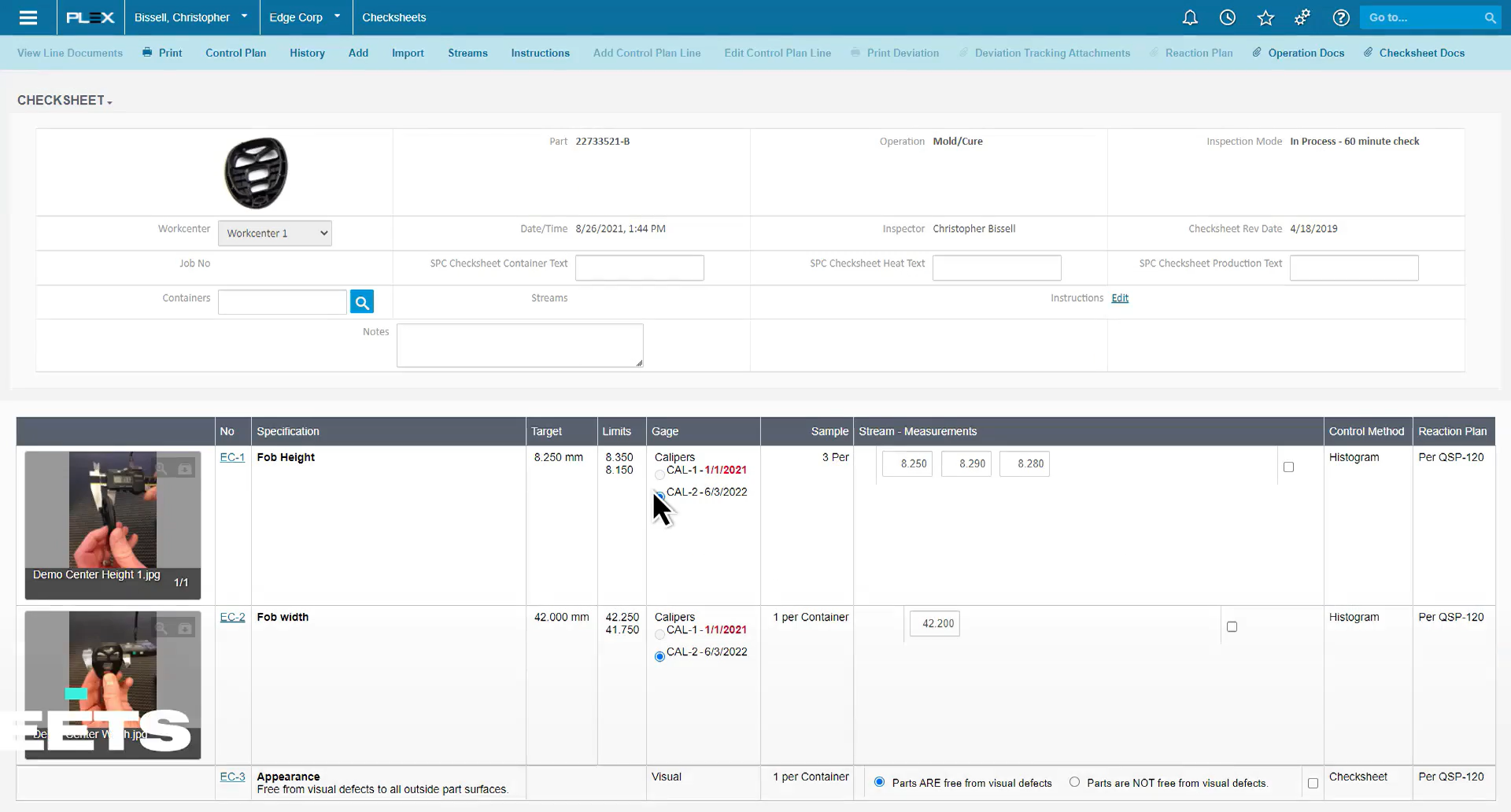

While inspection processing and results documentation can be tedious, MES systems make it much easier by incorporating quality management directly into production processes. This, in turn, helps us keep defects, rework, and recalls to a minimum. Instead of relying on manual checks or after-the-fact inspections, MES systems enforce process standards in real time, ensuring that each step is performed consistently and correctly.

Figure 7: Inline Inspection Results Recording with Plex MES

MES systems also streamline the quality inspection process. This means that operators receive immediate feedback if a measurement drifts out of spec, and automated alerts can flag issues before they result in wasted materials or defective products. This proactive approach not only reduces scrap but also speeds up response times when problems do arise.

Perhaps most importantly, MES systems provide full traceability from raw materials through to finished goods. That means you can demonstrate compliance with industry standards and regulatory requirements with confidence. In the event of an audit or customer inquiry, all the evidence needed is already captured in the system. If you've ever hastily pulled together an audit report or are staring at shelves of binders full of inspection forms, you can probably appreciate the amount of time this saves.

As the saying goes, what gets measured gets managed. By systematically measuring quality at every stage of production, MES systems give manufacturers the ability to not only meet standards but continually raise them. The end result is tighter control, fewer surprises, and stronger assurance to customers and regulators alike that your products meet the highest standards.

Closing Thoughts

Manufacturing is full of moving parts: people, machines, materials, and processes that all have to work in harmony. ERP systems provide the plans, but it’s MES systems that make sure those plans hold up on the shop floor. From improving efficiency and reducing costs, to enabling smarter scheduling, stronger supply chain collaboration, end-to-end traceability, and better quality, MES systems deliver the visibility and control manufacturers need to thrive.

At the end of the day, the value of adopting an MES system arguably comes down to one thing: precision. The more accurately you can measure and manage what’s happening in your plant, the more opportunity you have to improve performance and stay competitive. So, if you're looking to eliminate waste, minimize risk, and build a foundation for smart manufacturing, an MES system isn’t just a nice-to-have. It’s becoming an essential part of the modern production environment.